recycling old books

Amid global resource scarcity and increasingly stringent environmental laws, recycling traditional paper has become a crucial direction in the papermaking industry. Book paper, as a structurally stable, high-fiber-content paper type, is gradually becoming an essential source of recycled pulp. Compared with conventional waste paper materials like corrugated cardboard (OCC), magazine paper (OMG), or old newspaper (ONP), recycling old books not only reduces the volume of books sent to landfills but also strikes a favorable balance between environmental benefits and economic feasibility.

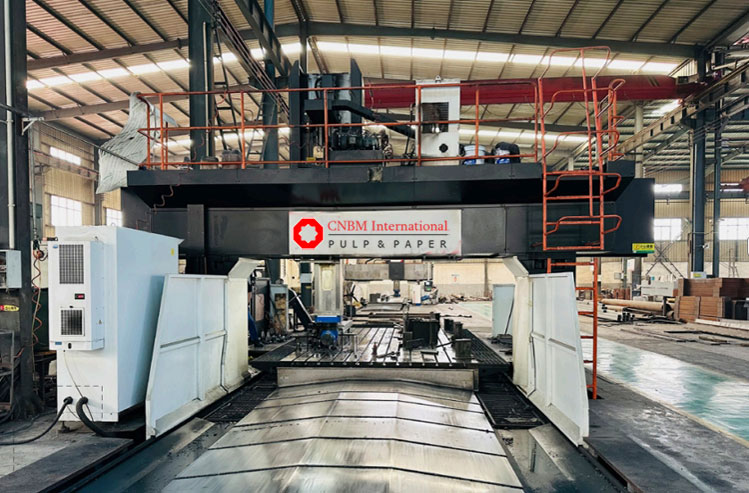

Anyang Machinery, with over 20 years of experience in papermaking equipment manufacturing and system integration, offers a one-stop pulping and re-papering system solution tailored for book paper recycling, assisting customers in building efficient, eco-friendly, and low-energy pulp production lines.

Features of Book Paper

Book paper mainly refers to recycled old books, textbooks, notebooks, bound documents, etc. Most of them are made from high-grade chemical or mechanical pulp. Their characteristics include:

- Thicker and stiffer paper suitable for recycled printing and office-grade cultural paper.

- Mostly hardcover books, textbooks, educational supplements, art books, etc., with no or light coating—ideal for de-inking.

- Some contain glue bindings, saddle stitching, plastic covers, and other impurities requiring specialized pretreatment equipment for removal.

- Major sources include schools, libraries, printing houses, and recycling centers.

- Suitable for producing recycled writing paper, cultural paper, packaging paper, and pulp-molded products.

Why Recycle Book Paper?

Old books (including magazines and archival paper) are an excellent source of high-quality recycled fiber:

✔ Long fibers: Book printing paper is often chemically pulped, giving stronger fiber strength than ordinary waste paper.

✔ Low impurity rate: Binding adhesives can be targeted for removal, making it easier to clean than mixed paper.

✔ Environmental premium: Cultural-grade paper aligns with ESG trends, enhancing product value.

✔ Mature de-binding: De-inking difficulty is higher than magazines but lower than packaging paper.

Most old books, like textbooks, bound magazines, or hardcovers, are no longer suitable for resale or reuse. By book disposal recycling, large numbers of outdated books are diverted from landfills. Compared to virgin pulp, recycled book paper pulp saves energy, reduces emissions, improves de-inking efficiency, and contains fewer contaminants.

Anyang Machinery old book paper pulping line and equipment

Anyang Machinery old book paper pulping line and equipment

Anyang Machinery’s Custom Book Paper Recycling Solution

Raw Material Pretreatment System

Intelligent sorting line – Removes non-paper impurities like bindings and plastic covers.

Adhesive separation technology – Low-temperature pulping and thermal dispersion systems efficiently break down spine glue.

Archival shredding option – Includes secure destruction modules at the pulping stage for sensitive documents.

Core Pulping Processes

▶ De-inking process (for high-brightness pulp)

Book paper → Hydrapulper (pH controlled) → Flotation de-inking cell (special agent) → multi-stage fine screening → hydrogen peroxide bleaching.

Yields 82–85% pulp with brightness ≥ 75% ISO.

▶ High-strength process (for packaging board)

Book paper → Chain pulper (fiber-protective) → High-consistency dirt removal → thermal dispersion → pulping refinement.

Tensile strength increases by 20% vs. standard waste pulp.

Finished-Product Oriented Transformation

Cultural-grade paper: newsprint or recycled printing/copier paper (requires de-inking + bleaching).

Packaging materials: eco box liners or molded trays (via high-strength process).

Specialty paper: decorative base sheets or flame-retardant paper (with functional additives).

Exclusive Support for Book-Waste Projects

Raw material testing – Free fiber analysis and adhesive content testing, tailored pretreatment solutions.

Glue processing equipment package – Includes low-temp pulper (to prevent adhesive melting), heat dispersion unit (grinds glue to <0.2 mm), and micro flotation cell (secondary glue removal).

Compliance assurance – Archival paper treatment meets ISO 15713 confidentiality-destruction standards; EU REACH-approved ink residue control.

Challenges & Solutions

| Challenge | Anyang Machinery’s Approach |

|---|---|

| Complex bindings (glues, staples) | High‑shear hydrapulper + alkaline softening |

| Diverse inks, low de‑inking rates | Flotation + dispersion + bleaching tailored to ink types |

| Contaminated pulp affecting quality | Multi‑stage screening + density–weight separation |

| Complex operation, high energy use | Fully automated control with energy management |

Recycled Book Paper Products and Application Fields

| Recycled Paper Type | Typical Application |

|---|---|

| Recycled printing/copy paper | Office printing and daily copy use |

| Educational paper / Recycled writing paper | Sticky notes, notebooks, exercise books, educational materials |

| Cultural printing paper | Brochures, manuals, book pages, instruction leaflets |

| Grey board / Recycled duplex board | Book covers, inner packaging board, appliance box lining |

| Pulp molded products | Industrial trays, food containers, eco-friendly paper packaging |

| Recycled kraft liner / packaging paper | E-commerce boxes, kraft paper bags, logistics packaging |

Eco & Economic Benefits

Recycling 1 t of book paper saves approx. 40% virgin wood fiber and cuts carbon emissions by over 30%. This not only lowers raw material costs but enhances brands' green images.

Why Anyang Machinery is Your Trusted Partner

✅ 20+ years of experience in pulp‑recycling systems.

✅ Over 100 waste paper pulp projects delivered.

✅ Independent patented de-inking and screening technologies.

✅ Complete export qualifications and international teams

✅ Turnkey solutions from design, equipment to installation, commissioning and training.

Whether you’re a pulp mill or full-scale papermaker, Anyang Machinery offers tailored, efficient, low-carbon, and intelligent book paper recycling solutions to help you achieve both economic returns and sustainable development.

Equipment Advantages from Anyang Machinery

Hydrapulper – handles glued, coated, and high-density book stocks.

Multi-stage flotation de-inking towers – deal with diverse book inks.

Pressure screen systems – remove large debris while preserving fiber strength.

Disc Filter washing units – ensure pulp purity.

Automated control system – visual, remote-operable, easy to manage.

Book paper isn’t merely obsolete library or home books—it can be efficiently converted into high-value recycled pulp and green paper through book paper recycling, recycling old books, etc. Anyang Machinery is committed to global leadership in book-waste-to-paper solutions, helping companies reduce costs, enhance resource utilization, and boost environmental credentials.