pulp digester

What is pulp digester?

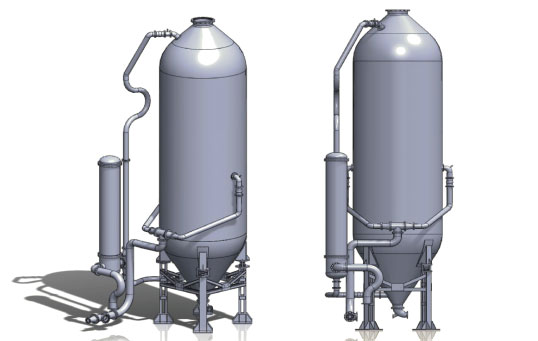

Pulp digester, also called digester, is a huge container for chemical pulping and dissolved fiber steam sections. It is used to cook raw materials of paper pulp, such as grass, wood, boom and so on. Pulp digester is not only apply for kraft process but also sulfite process. The raw materials of digester have carbon steel structure, composite steel structure, dual phase stainless steel due to the difference of alkaline pulping and acid pulping process.

As our main product, we can produce various specifications including 50m³、75m³、110m³、135m³、175m³、225m³、250m³、400m³. Among them the maximum diameter is 5.8 meters and the maximum volume is 400 cubic meters. Customers can choose the most suitable pulp digester according to the real requirements.

Working principle of pulp digester

- Before cooking, all raw materials must keep moisture content below 15 percent, silicon less than 3 percent, ash about 2-3 percent and cellulose about 50-55 percent.

- First, cut the raw material into about 25 by 30mm slices and feed them into the cooker through the conveyor belt.

- The requirements of pulping process usually determine the length of cooking process, in particular, the length of cooking process depends on the yield and hardness of pulp. Cooking usually lasts 5-6 hours, during which cooking temperature should be kept at 160-175 ℃.

- The heating process mainly refers to the indirect heating area of the tube heater. The liquid from the center flows through the tube and heats up and moves from the top to the bottom. Next, reheat the liquid about 8-12 times an hour. At the same time, the steam enters the auxiliary heating through the vent at the bottom.

- In the course of cooking, gas is released through the upper vent to reduce the false pressure caused by the air inside the cooker, to ensure the pulp cooking uniformity and to improve the pulp quality.

- After cooking, under pressure, remove the pulp from the cooker and enter the discharge tank for temporary storage.

Generally, according to the different pulping process, there are vertical digester and horizontal digester in the chemical pulping productions.

Vertical digester

In general, vertical digesters are used for super-batch cooking. We use the most advanced batch cooking process-displacement cooking process, efficient and low-cost and high-quality pulp. So here vertical digester can be called displacement digester.

Displacement digester specifications:

|

Model |

ZJG3 |

ZJG4 |

ZJG5 |

ZJG6 |

ZJG7 |

ZJG8 |

ZJG9 |

|

Effective volume (m³) |

110 |

135 |

175 |

225 |

250 |

330 |

400 |

|

Diameter (internal) (mm) |

3600 |

4000 |

4500 |

4500 |

4500 |

5600 |

5800 |

|

Design pressure(Mpa) |

0.9/1.2 |

||||||

|

Design temperature (℃) |

180/240 |

||||||

Horizontal digester

Continuous cooking is a widely used pulping process at present, which has many advantages over traditional pulping technology. Please refer to pulp cooking process for details. Horizontal digester is an important part of continuous cooking process. The digester is mainly used in pulping of various raw materials, including wood chips and loose and permeable materials such as bagasse, wheat grass, reed and straw etc.

If you are interested in our paper pulp digester or have any questions about digester for paper pulp process, please don't hesitate to contact us! We are always at your service!