displacement digester

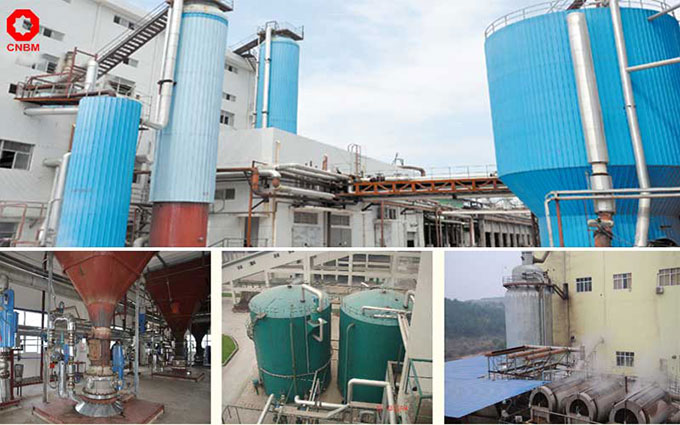

Composition of displacement digester system

Displacement digester cooking system is the most advanced batching cooking technology all over the world, it consists of conveyor, digester, separator, storage tank, blow tank, heat exchanger, foam crusher, black liquor filter and pump. It is with high technology, can cook raw materials high efficient so as to make high quality paper pulp.

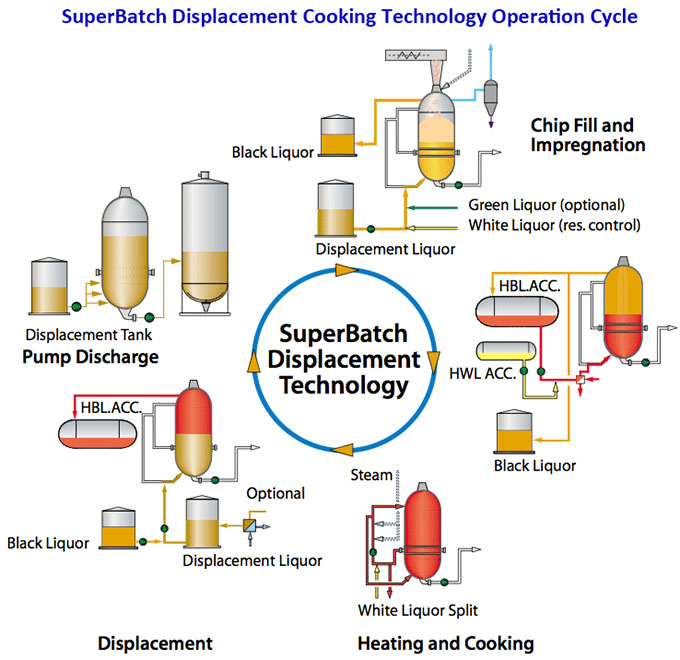

Operational principle of displacement digester cooking system

Displacement digester cooking system consists of four basic units, namely, cooking, heat exchange, black liquor filter and waste gas separation. The cooking process consists of the following five steps:

Disgester filling: transfer raw material through conveyors to the digester, add recyclable black liquor, and remove the air from the digester with an exhaust device.

Impregnation process: the black liquor in the dipping tank is transferred to the pulp cooker by pump, the cold white liquor is added quantitatively, the black liquor is removed from the last step, and the air is discharged from the cooker.

Low temperature cooking process: the black liquor is transferred from the dipping tank to the pulp cooker by pump, the hot white liquor is added quantitatively, the black liquor in the impregnation process is replaced, and the cooker is heated to the cooking temperature.

High-temperature cooking process: compared with common ingredients cooking process, use the external circulation system to heat to cooking temperature.

Replacement washing process: use washed and filtered black liquor instead of digester black liquor.

Advantages of displacement digester cooking system

- Displacement digester cooking technology is the most advanced batch cooking technology in the world. Compared with traditional cooking, it has the following advantages:

- Steam consumption of tonnage pulp is greatly reduced to 0.6-0.8 tons and steam consumption is greatly reduced.

- The pulp with low Kappa number, high strength and high yield can be achieved by deep delignification. Short cooking cycle and high production efficiency.

- Suitable for wood and bamboo fiber materials with poor quality and low pass rate.

- The production process is automatically controlled by computer and minimizes manual operation to ensure the reliability and stability of the system.

- Cold blowing technology, no noise, can reduce 95% of exhaust gas, reduce environmental pollution.

| Model | ZJG3 | ZJG4 | ZJG5 | ZJG6 | ZJG7 | ZJG8 | ZJG9 |

| Effective volume (m³) | 110 | 135 | 175 | 225 | 250 | 330 | 400 |

| Diameter (internal) (mm) | 3600 | 4000 | 4500 | 4500 | 4500 | 5600 | 5800 |

| Design pressure(Mpa) | 0.9/1.2 | ||||||

| Design temperature (℃) | 180/240 | ||||||