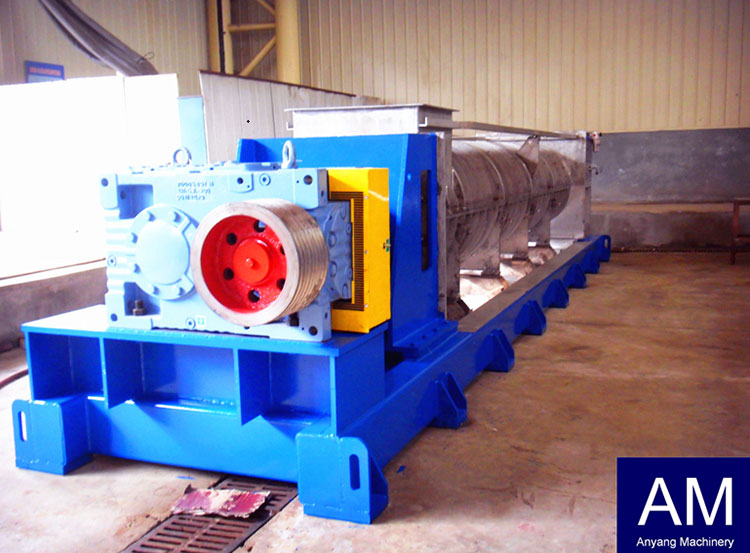

single screw press

About single screw press

Single screw press is the ideal equipment for the comprehensive utilization of black liquor in pulping and paper mill, which can be used for the black liquor extraction of pulp and also for the black liquor extraction of waste paper deblackening pulp. The suitable pulp contains wood, bamboo, bagasse, wheat grass, reed and so on.

The single screw press can deal with all kinds of slurry with different injection concentration effectively. The dry degree of the concentrated pulp is uniform and the pulping rate is stable. Fiber tapping degree is rarely affected, no blockage, no skid design to reduce the wear and corrosion of the screw. It is mainly used for the extraction of black liquor from large pulp mill: it is installed in the ejection bin and separated from the pulp by mechanical extrusion with variable diameter and pitch helix, and the black liquor is separated from the filter frame to the black liquor trough. The equipment can also be used to concentrate finished pulp and sell it directly as commercial pulp.

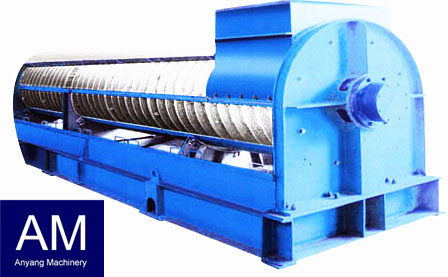

Structure of single screw press

Single screw press has many parts including feeding bearing, screw shaft, main bearing, filter drum, intermediate support, reel, feed port, foot section, a discharge port, rack, hood, air cylinder, loading plug, transmission and etc.

The main components of a single screw press are as follows:

Transmission: frequency converter, motor, reducer, coupling, etc. The speed of spindle can be adjusted by frequency converter. When the speed of the screw shaft increases, the production capacity of the equipment can be improved. When the speed of the screw shaft decreases, the drying degree of the output material can be improved.

Screw shaft: first, the pulp is connected with the screw conveyor. In the middle part, the screw shaft increases the compression ratio, the filtrate extraction rate and the pulp drying degree. Finally, the rear part is a high pressure screw, from the inlet to the discharge port, the screw pitch of the screw is sorted from small to large.

Sieve drum: including inlet part, pre-filtration part, compression part and outlet part, etc. The inner layer of the sieve tube is a mesh, made of stainless steel plate, the aperture from the entrance to the outlet from small to large.

Technical parameters(AMDL-I series)

Note: Based on kraft wood pulp

| Model/Specification | AMDL-I 600 | AMDL-I 750 | AMDL-I 1000 | AMDL-I 1100 | AMDL-I 1200 | AMDL-I 1500 |

| Screw Dia.(mm) | 600 | 750 | 1000 | 1100 | 1200 | 1500 |

| Production (Kt/d) | 40-50 | 50-70 | 100-120 | 120-140 | 140-160 | 180-200 |

| Power (KW) | 37 | 45 | 55 | 75 | 90 | 132 |

| Net Weight (Kg) | 14000 | 16000 | 19000 | 21000 | 24000 | 32000 |

| Inlet Consistency(%) | 8~12 | 8~12 | 8~12 | 8~12 | 8~12 | 8~12 |

| Outlet Consistency (%) | 25~35 | 25~35 | 25~35 | 25~35 | 25~35 | 25~35 |

Technical parameters(AMDL-II series)

Note: Based on kraft wood pulp

| Model/Specification | AMDL-I 600 | AMDL-I 750 | AMDL-I 1000 | AMDL-I 1500 |

| Screw Dia.(mm) | 600 | 750 | 1000 | 1500 |

| Production (Kt/d) | 50-100 | 100-120 | 200-350 | 500-700 |

| Power (KW) | 90 | 160 | 315 | 500 |

| Net Weight (Kg) | 9200 | 12500 | 19000 | 38000 |

| Inlet Consistency(%) | 4~12 | 4~12 | 4~12 | 4~12 |

| Outlet Consistency (%) | 25~30 | 25~30 | 25~30 | 25~30 |

Advantages

- Low rotate speed, low power demand and low noise.

- Special structure of design to prevent pulp slippage and reach high discharge consistency of pulp.

- High dewatering efficiency, extracting 80% of black liquor from the pulp, high dryness of pulp.

- Applicable pulps: straw pulp, bamboo pulp, bagasse pulp, wood pulp, etc.

- Shell design: to prevent overflow of peculiar smell and black liquor.

- Completely mechanical extrusion dewatering, installation height isn’t needed.