old magazine recycling

As the demand for sustainable papermaking solutions increases, the efficient recycling of waste paper has become a core focus in the paper industry. Among various waste streams, Old Magazine Paper (OMG) stands out as a valuable yet underutilized raw material. With its glossy coatings, vivid inks, and high fiber content, OMG offers great potential for producing high-quality recycled pulp, while also posing unique technical challenges.

Under growing environmental pressures and rising raw material costs, paper mills are actively seeking new fiber sources. Recycling OMG provides an innovative solution to help manufacturers reduce virgin pulp consumption, lower production costs, and promote eco-friendly paper production.

Anyang Machinery operates a modern production base covering over 220 mu (36 acres) with 40,000 square meters of workshops and more than 310 sets of advanced processing equipment. Our facilities include CNC cutting, riveting, precision machining, assembly, surface treatment, and painting workshops. This robust infrastructure enables us to fully leverage advanced technologies for the recycling of coated magazine paper.

We specialize in delivering customized deinking and pulping solutions for OMG recycling. Whether you are producing printing paper, tissue base sheets, or other recycled products, our team provides a complete one-stop service, from raw material analysis to system design and equipment installation.

If you're looking for a reliable partner in Old Magazine Paper recycling, contact us today. Let us help you build a cleaner, greener, and more efficient paper production line.

What is Old Magazine Paper (OMG)?

Old Magazine Paper (OMG) refers to post-consumer glossy magazines that are collected and recycled as a source of secondary pulp material. These magazines are typically made from high-grade groundwood pulp or chemical pulp, and feature the following characteristics:

- Coated mechanical paper used in printing.

- Pages with high gloss and heavy ink coverage.

- Surface coatings containing clay or calcium carbonate.

- May include staples, glue residues, or plastic film wrap.

Compared to other waste paper types like Old Corrugated Containers (OCC) and Old Newspapers (ONP), OMG offers finer fibers, lower lignin content, and higher natural brightness. When properly processed using advanced deinking and pulping systems, OMG becomes a reliable raw material for producing high value-added recycled paper, such as: lightweight coated (LWC) paper, printing and writing paper, recycled tissue base sheets and specialty paper products.

OMG is especially suitable for paper mills looking to expand their glossy paper recycling capabilities, reduce reliance on virgin pulp, and support a circular economy in the publishing and packaging sectors.

Old Magazine(OMG) Recycling Process

Collection and Sorting

Old Magazine Paper (OMG) is separated from Mixed Office Waste (MOW) and Old Newspapers (ONP) to ensure consistent fiber quality. Proper sorting is essential to prevent contamination from other paper types.

Pulping and Screening

Using hydrapulpers or drum pulpers, OMG is broken down into fibers. Fine screening systems are applied to remove contaminants such as coatings, adhesives, and residual inks.

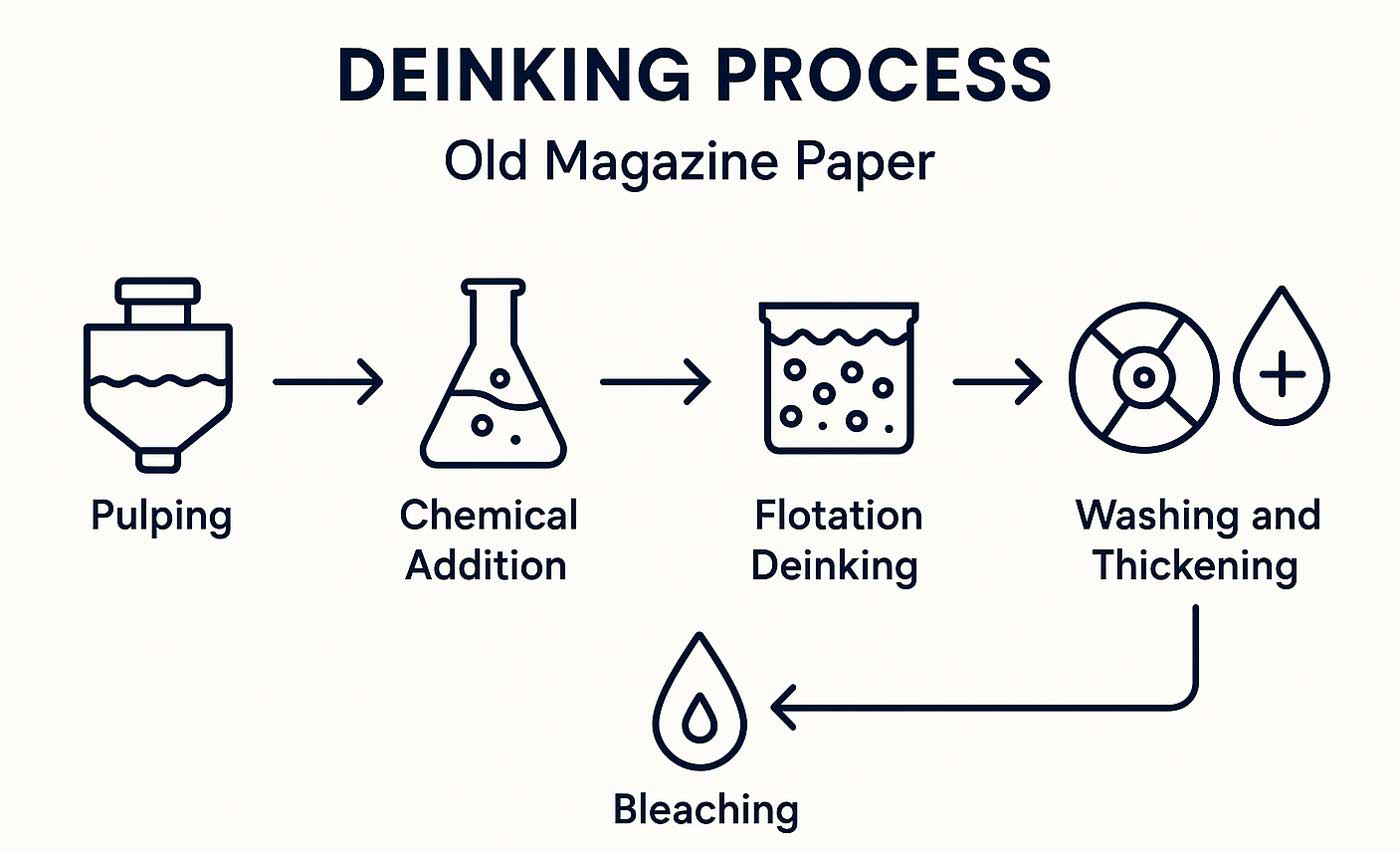

Deinking Process for Old Magazine Paper

The deinking stage is the most complex and critical part of the OMG recycling process. Unlike newspapers or OCC, magazine paper contains strongly adhered oil-based, UV-cured, or heat-set inks, which are difficult to remove through conventional methods. The presence of clay or calcium carbonate coatings on the paper surface further complicates ink removal by interfering with surfactant adsorption and ink-fiber separation. Therefore, OMG deinking requires specialized multi-stage processes to achieve clean, high-quality recycled pulp.

Recommended Deinking Process Configuration

(1) Pre-treatment Stage

Waste OMG is soaked in warm water and mixed with alkaline chemicals (e.g., NaOH) and dispersants to soften the coating and release ink particles. Chelating agents (e.g., EDTA) are added to neutralize metal ions that may hinder chemical reactions.

(2) Main Deinking Stage

A multi-stage flotation deinking system is applied, using air bubbles to lift ink particles from the pulp. For enhanced efficiency, mechanical agitators or hydrocyclones may be used.

(3) Washing and Thickening

Disc filters or twin wire presses are used to remove remaining fine contaminants and coating residues. The pulp is further thickened to stabilize solids content and purity.

(4) Optional Bleaching

For high-brightness pulp applications, hydrogen peroxide (H₂O₂) or oxygen-based bleaching may be used to increase whiteness without damaging fiber structure.

Key Process Control Points

- Temperature: Maintain 45–55°C to soften ink and coating layers.

- PH Level: Keep between 9–10 for optimal ink dispersion and removal.

- Chemical Dosing: Adjust dosing based on ink type and coverage to balance cost, efficiency, and pulp quality.

Typical Equipment for OMG Recycling

Anyang Machinery offers high quality deinking equipment, they are designed for deinking high-strength waste paper, including ONP, OMG, and MOW:

- High-consistency hydrapulper.

- Multi-stage flotation deinking cell.

- Disc filter washing system.

- Screw press or twin wire press dewatering system.

With a properly configured deinking line, OMG can be efficiently converted into high-quality recycled pulp, suitable for various end uses like printing paper, tissue base sheet, and recycled board. This process helps promote the circular economy in the paper industry.

Why Recycle OMG for Pulping?

1. High Fiber Quality

Old Magazine Paper (OMG) contains uniform short fibers with good strength, offering an ideal balance between printability and surface smoothness. This makes OMG a reliable source of secondary pulp.

2. Suitable for Various Paper Products

Recycled OMG pulp is widely used in the production of: printing and writing paper, tissue base paper, coated duplex board and specialty papers.

3. High Brightness and Smoothness

Thanks to its surface coating and fine fiber structure, OMG pulp—after deinking—features high brightness and a smooth surface, reducing the need for additional bleaching or intensive chemical treatments.

4. Abundant Supply

Large volumes of magazines are discarded globally each year. OMG is readily available through urban recycling systems, offices, and publishing distribution chains, making it a consistent and scalable raw material for papermaking.

Environmental Benefits of OMG Recycling

✅ Reduces Glossy Paper Landfill Waste

Coated magazine paper is hard to degrade in landfills. Recycling OMG prevents this waste from entering incineration or landfill systems, minimizing land use and secondary pollution.

✅ Saves Virgin Fiber and Reduces Deforestation

OMG pulp, made from high-quality groundwood or chemical pulp, can partially replace virgin fiber—especially in the production of coated paper, tissue, and writing grades—helping conserve forest resources.

✅ Lowers Carbon Footprint

Recycling OMG consumes less energy and emits fewer carbon emissions compared to virgin pulp production. When integrated into existing waste paper processing lines, it also reduces transportation and operational energy needs—supporting corporate carbon neutrality goals.

✅ Supports Circular Economy in Publishing and Packaging

OMG originates mainly from publishing and packaging sectors. Establishing a closed-loop supply chain—from distribution and consumption to recycling and re-manufacturing—enhances brand sustainability and supports low-carbon transformation in the publishing, printing, and packaging industries.