Pulp Washing

The purpose of washing is to separate the pulp from black liquor to wash out the residual substances such as alkali-lignin produced in the cooking process, purify the pulp for the purpose of screening and bleaching, and separate the pulp from black liquor. At the same time, the pulping waste liquor with high concentration and temperature was put forward to the wastewater treatment, and the organic or inorganic substance in the waste liquor was recovered by acid and alkali recovery process.

The principle of washing: unwashed pulp, most of the waste liquid exists in the flow space between fibers (about 70-80% of the total amount of liquid), partly in the inner channel of the fiber cell (about 15-20% of the total fluid), and only a few in the interstitial space of the fiber wall (5%). Pulp washing is actually a process of filtration and diffusion. Filtration and diffusion are inseparable.

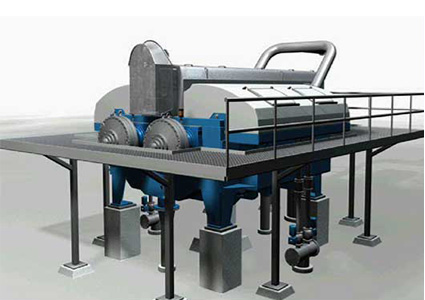

vacuum drum washer

We offer vacuum drum washer with the advantages of large yield per unit area, high vacuum degree stable and high-density feed, easy maintenance and operation, low consumption....

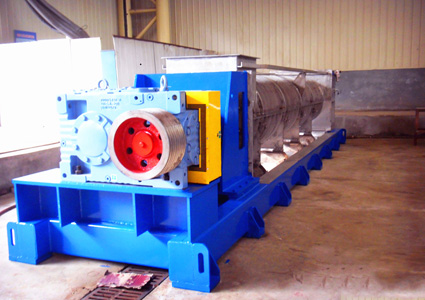

Read Moretwin roll press

CNBM offers twin roll press with high efficiency for extracting pulp black liquor and washing with excellent after-sale service. Be free to contact!...

Read Moredisc filter

Disc filter, a vacuum negative pressure driven solid-liquid separation equipment for paper pulp thickening and white water recovery, is used in washing or bleaching process....

Read Moregravity disc thickener

We are superior gravity disc thicken manufacturer, it is mainly used for thickening or washing of low consistency pulp. It is easy to install & operate....

Read Moresingle screw press

Single screw press is the ideal equipment to deal with slurry with different injection concentration. We offer high quality and low price single screw press, welcome to contact us!...

Read More