How to treat the water of pulp and paper industry

In recent decades, due to factors such as rising energy prices, the pulp and paper industry has faced increasing cost pressures. Without affecting the quality of the product, is there any good way to effectively reduce costs? Some experts have found that the key lies in strengthening industrial water conservation and improving water efficiency.

As the "good partners" of paper mills, experts have always focused on papermaking and industrial water treatment technology. Solving problems for factories and enterprises and solving water treatment problems has been our consistent mission for more than 100 years. Combining professional knowledge and rich experience accumulated in the water consumption industry, the experts have developed a series of innovative chemical and equipment technology combinations.

Whether it is to reduce production and operating costs, or extend equipment life, improve productivity and product quality, experts can tailor scientific solutions to meet your needs.

If you are also worried about water treatment issues, you must not miss our article. Hurry up and listen to what the experts have in the field of water treatment!

Customized water treatment solutions

For different types of water, such as raw water, boiler water, cooling water and wastewater, we provide customized technical solutions to help customers reduce the chemical oxygen demand (COD) load in the water on the one hand, and reduce sludge in the production process on the other hand. Through the improvement of water treatment efficiency, the efficiency of pulp production can be improved.

Raw water treatment

Due to the different quality of raw water around the world, experts tailor raw water treatment solutions for each customer to meet their specific needs.

Experts are good at using a variety of technologies to improve raw water treatment effects, including turbidity and color control, the use of high molecular weight coagulants and flocculants to remove pollutants, and raw water microbial (MB) control.

With scientific treatment technology and diversified product portfolio, experts help pulp and paper manufacturers produce products that meet quality standards, improve the efficiency of raw water treatment, and protect paper machines.

Boiler water treatment

In the water pretreatment stage, the use of membrane scale inhibitors can effectively reduce the generation of precipitation and scale and extend the life of the equipment. Microbial control procedures and membrane cleaning products and services can help realize the recovery of high-purity water, avoid unplanned maintenance and cleaning procedures, thereby saving water, reducing costs and improving energy efficiency.

In addition, experts provide a variety of environmentally friendly solutions to prevent boiler corrosion and fouling problems, so as to ensure the good and safe operation of boilers and steam systems.

Existing boiler water treatment technology can perform automatic leak detection and effectively control the use of CMR (carcinogenic, mutagenic, reoxidized) graded products to produce products that meet national quality standards.

Cooling water treatment

We have a complete set of cooling water treatment solutions that can help save water to ensure the normal operation of open circulating cooling systems, closed and one-way water supply systems. Even under different PH conditions, various water treatment chemicals can work together.

The scientific cooling water treatment plan helps to improve the stability of the system and the efficiency of the heat exchanger, thereby further improving the water treatment effect. The use of cooling water chemicals can also reduce water consumption and the formation of adsorbable organic halogens (AOX).

Wastewater treatment

Wastewater treatment requires the use of coagulants and flocculants, which help to remove solids, reduce the chemical oxygen demand load in water and improve sludge dewatering. We also provide a series of odor suppression products for the factory to manage sludge and wastewater treatment areas.

The current wastewater treatment plan is cost-effective, helps reduce the cost of sludge treatment, and increases the recycling rate of water.

Some factories rely on a series of water treatment product portfolios and environmentally friendly solutions to effectively ensure the safety of staff and continue to escort the production of factories and enterprises.

Conclusion

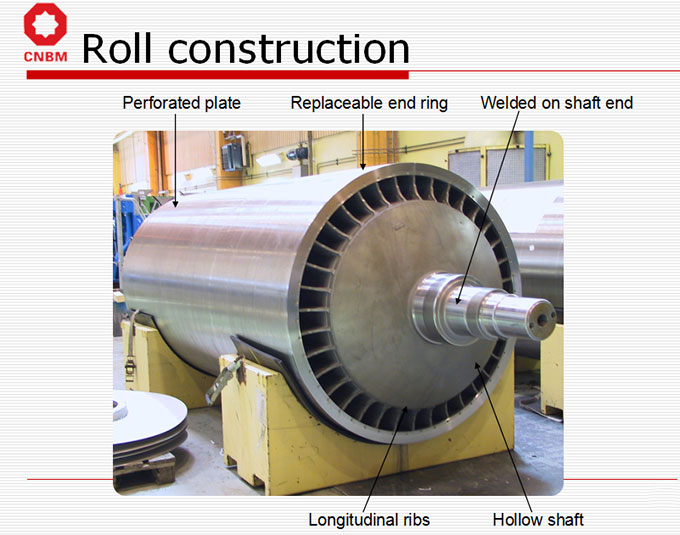

Water of pulp and paper treatment is quite important during the process of pulping. CNBM offers vacuum drum washer to extract various pulp and bleaching section in pulp and paper enterprises. What’s more, twin roll press is a new type of high efficiency equipment for extracting pulp black liquor and washing and concentrating. And disc filter is a vacuum negative pressure driven solid-liquid separation equipment for white water recovery and paper pulp thickening. All of the equipment is high quality and reasonable price. So if you want to occupy in the paper pulping industry, CNBM is your perfect choice. Moreover, CNBM offers custom-designed solutions for various materials, including wood, straw, bamboo, cotton, waste paper, reed and etc. We have nearly 30 years of experience in the field of pulp and paper machinery, We offer one-stop service for customers. We are ready to satisfy you. Come on now to get your bright future!

Technical parameters of twin roll press

| Model /Item | Drum length (mm) | Drum Dia. (mm) | Drum Speed (rpm) | Feed Consistency(%) | Discharge Consistency (%) | Production Capacity | ||

| Straw / Bagasse pulp | Bamboo pulp | Wood pulp | ||||||

| AMSG712 | 1200 | 700 | 2~20 | 3.5~10 | 20~35 | 30~40 | 60~80 | 80~100 |

| AMSG915 | 1550 | 900 | 2~15 | 3.5~10 | 20~35 | 40~60 | 85~120 | 130~160 |

| AMSG920 | 2000 | 900 | 2~15 | 3.5~10 | 20~35 | 55~85 | 125~160 | 175~210 |

| AMSG928 | 2820 | 900 | 2~15 | 3.5~10 | 20~35 | 80~120 | 165~220 | 250~300 |

| AMSG935 | 3500 | 900 | 2~15 | 3.5~10 | 20~35 | 110~150 | 225~280 | 310~370 |

| AMSG940 | 4000 | 900 | 2~15 | 3.5~10 | 20~35 | 120~170 | 220~310 | 350~400 |

| AMSG945 | 4500 | 900 | 2~15 | 3.5~10 | 20~35 | 160~180 | 285~350 | 400~480 |

| AMSG1532 | 3200 | 1500 | 2~15 | 3.5~10 | 20~35 | 220~350 | 450~600 | 700~800 |

| AMSG1540 | 4000 | 1500 | 2~15 | 3.5~10 | 20~35 | 400~550 | 800~1000 | 1200~1500 |

| AMSG1550 | 5000 | 1500 | 2~15 | 3.5~10 | 20~35 | 500~650 | 1000~1300 | 1700~1800 |

| AMSG1572 | 7200 | 1500 | 2~15 | 3.5~10 | 20~35 | 750~1000 | 1500~1800 | 2500~3000 |