Bamboo pulping and papermaking-the efficient use of bamboo fiber

Papermaking is one of out country’s four great inventions. In the Eastern Han Dynasty, Cai Lun used bark, broken fishing nets, rags, hemp, etc. as raw materials to produce plant fiber paper suitable for writing on the basis of summing up the experience of the predecessors in making silk crystals. The improvement of papermaking technology makes paper a commonly used writing material. Starting from the Jin Dynasty, bamboo was found to be used as a raw material for papermaking. As a result, China's papermaking history has also turned a new page.

Professor Chen Lihui from the School of Materials Engineering of Fujian Agriculture and Forestry University has been “communicating with bamboo” for more than ten years and has devoted himself to research bamboo, especially the research on bamboo fiber papermaking technology.

Bamboo papermaking, environmental protection starts from the source

In recent years, with the gradual deepening of the concept of environmental protection, bamboo papermaking, a technology that has been passed down for nearly a thousand years, has once again attracted public attention. Compared with traditional wood fiber papermaking, what is the difference between bamboo papermaking? A few days ago, the reporter interviewed Professor Chen Lihui from the School of Materials Engineering, Fujian Agriculture and Forestry University.

According to Chen Lihui, Chinese bamboo fiber papermaking began in the Jin Dynasty, and Europeans did not master the technology of making paper with non-linen materials such as bamboo and thatch until the 19th century. Judging from the time when the craftsmanship was produced, the bamboo papermaking craft in China was more than a thousand years earlier than in Europe. At first, the ancients could not divide the bamboo fiber into filaments, so that the paper produced was rough. Later, with the advancement of technology, the paper produced from bamboo pulp became more delicate and flexible, which was favored by scholars.

Chen Lihui told reporters the main chemical components of bamboo include cellulose, hemicellulose and lignin. In the process of pulping and papermaking, it is usually necessary to remove lignin and retain cellulose and hemifibres. Compared with wood, bamboo has a higher density. The cooking liquid is more difficult to penetrate and the removal of lignin is more difficult. In ancient times, tender bamboos were usually used for pulping and papermaking. The density of tender bamboos was low and the lignin content was low, which was beneficial to the penetration of the cooking liquid and the removal of lignin. With the innovation of pulping and papermaking technology, the use of bamboo to make bleached bamboo pulp can be cooked with deep delignification technology and bleached with multi-stage chlorine-free bleaching technology, with less carbohydrate degradation, high yield and high strength of bleached bamboo pulp, and the production process of pollution is low.

For the paper industry, wood is an excellent raw material for papermaking. However, our country's forest coverage rate is far below the global average of 31%, and the per capita forest area is only 1/4 of the world average.

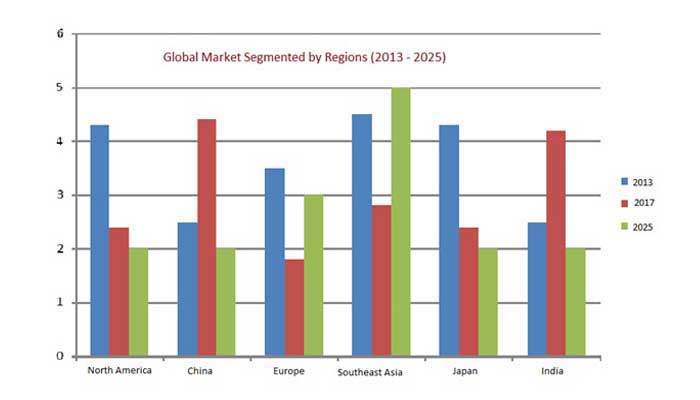

The "Thirteenth Five-Year Plan for Forestry Development" pointed out that vigorously develop forest tourism, under-forest economy and wood and bamboo product processing parks, develop high-quality, high-yield and high-efficiency bamboo forests, strengthen the construction of key counties for the development of the bamboo industry, and strengthen the targeted cultivation of bamboo forest resources. Develop the bamboo processing industry and improve the intensive management of the bamboo industry. By 2020, the total output value of the bamboo industry will reach 300 billion yuan.

Our country's bamboo resources, bamboo forest area and stock volume rank first in the world, and it is known as the "Bamboo Kingdom". In this context, the development of bamboo pulp and paper will help alleviate the shortage of wood in our country's pulp and paper industry and help to protect the ecological environment. Bamboo has the advantages of fast growth, short cycle, and renewable. Bamboo is an excellent raw material for papermaking. Innovative bamboo pulping and papermaking technology can achieve high-value utilization of bamboo resources, which will help adjust the bamboo industry structure and promote the economic development of bamboo production areas. It is important for farmers to get rich.

Efficient use of bamboo fiber

The morphology of bamboo fiber is between coniferous wood fiber and hardwood fiber, and the performance of bamboo pulp is between coniferous wood pulp and hardwood pulp. Using bamboo as raw material can produce pulp and dissolving pulp. Pulp can be used to make paper, while dissolving pulp can be used as textile material. To produce dissolving pulp with bamboo as a raw material, it is not only necessary to remove lignin, but also to remove hemicellulose. Bamboo dissolving pulp is used as raw material to produce viscose fiber. The traditional process uses carbon disulfide as the solvent, which has the disadvantages of long production cycle, low fiber strength and serious pollution in the production process, and the production process will produce carbon disulfide and hydrogen sulfide and other toxic gas pollution.

Through technological innovation, our project team used pollution-free organic solvents instead of carbon disulfide to solve the core key technology of bamboo regenerated fiber production-the technical problems of inability to continuous spinning and low solvent recovery rate, and developed a pollution-free bamboo regenerated fiber during the production process.

There are two innovations in the key technology and functionalization of bamboo fiber preparation. One is the development of key technologies for the preparation of bamboo pulp and dissolving pulp; the other is the development of bamboo pulp short fiber textile materials to replace the traditional viscose fiber production process with serious pollution during the production process. The key technology of bamboo fiber preparation developed by this project can solve the problems of poor performance, high energy consumption and heavy pollution of traditional bamboo fiber, and realize its high-value application in textile, packaging, decoration and other industries.

We can offer not only vertical pulper, but also horizontal pulper. Here are the different specifications of pulpers for bamboo pulp making you can refer to.

| Rotary Spherical Digester | Vertical Digester | Continuous Tubular Digester | |

|---|---|---|---|

| Capacity(dry bamboo chips) | 180-220kg | 220-230kg | 110-160kg/min |

| Liquor ratio | 1:2.4-3 | 1:3-3.5 | 1:2.4-2.8 |

| alkali charge(sodium cyanide) | 18%-22% | 15%-18% | 18%-20% |

| sulfidity | 15%-25% | 16%-22% | 18%-20% |

| maximum cooking pressure(MPa) | 0.55-0.65 | 0.65-0.7 | 0.6-0.7 |

| maximum cooking temperature | – | Around 165 | 165-170 |

| heating method | Direct heating | Indirect heating and direct heating | Direct heating |

| cooking time | 4h | 4-5h | 45-48min |

| brown pulp hardness | 10-18 | 14-18 | 14-18 |

| residual alkali of black liquor | 9-16g/L | 10-16g/L | 10-16g/L |