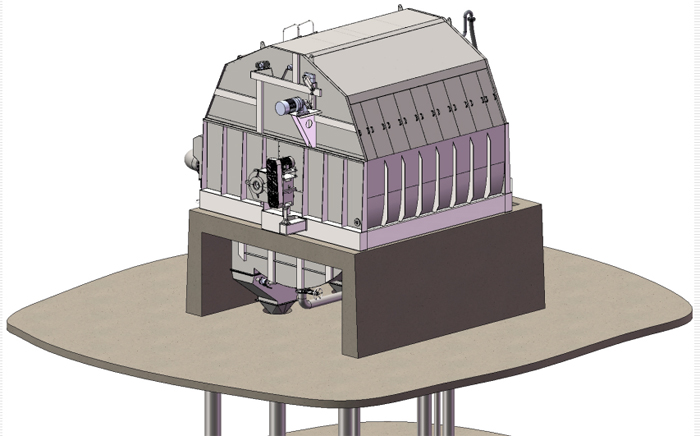

ZNH series vacuum filter working principle

ZNH series multi-disc vacuum filter is used for water treatment. It is to remove suspended solids, inorganic ions and colloids, incompatibility and capacitive organic substances in water reuse, and good water treatment system for production water. Closed circulation is of utmost importance. Some enterprises cannot properly close the cycle because they do not have a suitable water treatment system. The most important papermaking wastewater is white water. The methods for extensive treatment of white water are mainly disc filters or air floaters. The device can effectively remove suspended solids and some organic matter from the water, but cannot remove the capacitive inorganic ions from the system.

Working principle of ZNH series vacuum filter

The ZNH series multi-disc vacuum filter is a continuous rotary filter device that uses the vacuum generated by the vertical water leg as the filtering power and circulates the filter disc on the multi-disc spindle through the distribution valve: natural filtration zone, vacuum filtration zone. Different working areas such as stripping area and washing area can realize white water filtration or slurry concentration function.

When the filter disc is rotated below the liquid level, the filter disc enters the atmospheric filtration zone. The slurry in the tank is discharged through the filter through the main shaft and the outlet of the distribution valve atmospheric zone filtrate under static pressure. The main shaft continues to rotate, and the sector plate enters the vacuum filter zone. The liquid in the tank body passes through the slurry layer, the filter screen, and the main shaft enters the water leg from the distribution valve to form a vacuum, and the liquid penetrates the filter mesh and forms a filter cake. In the initial stage of vacuum filtration, the filter cake is thinner, and some fibers and fillers pass through the filter net together with the filtrate to form a turbid filtrate. As the filter cake is thickened, the filtration effect of the filter cake is strengthened, and the filtrate is cleared to form a clear filtrate. The turbid filtrate and the clear filtrate flow from the two water legs to the clear and turbid filtrate pool, respectively.

When the fan-shaped plate is turned out of the liquid surface, the vacuum does not disappear immediately, and the filter is still filtered. The pulp layer on the net continues to dehydrate and the concentration continues to increase. The spindle continues to rotate.

The effect disappears and the sector plate enters the stripping zone. At this time, the stripping nozzles on both sides of the filter disc are sprayed. The fan-shaped water flow peels off the slurry layer and falls into the receiving hopper, which is then washed down by the flushing pipe and dilute and discharge to the slurry tank through the outlet of the screw discharger or the discharge hopper.

When the filter disc is rotated to the washing area, the net is washed by the oscillating washing nozzle to restore the filtering capacity and then enter the next filtration cycle. As the filter disk continues to rotate, the sector plates are in different zones, producing continuous filtration that continuously recovers fibers and fillers from the white water.