Study on enhanced nodes of cellulase-assisted refining

The biological enzyme has the advantages of mildness, specificity, high efficiency and adjustability, and the enzyme pretreatment can improve the pulp fiber and reduce the energy consumption of beating. Domestic and foreign scholars have used different cellulase, hemicellulase or combination to study the application of biological enzymes in pulp refining, and pointed out that bio-enzymes can reduce the energy consumption of pulping, reduce the steam consumption of paper machine and increase the paper strength.

At present, bio-enzyme-assisted refining technology has a wide range of applications, but there are still many technical problems to be solved in production practice. For example, the research on bio-enzyme-assisted energy-saving beating mainly focuses on the field of beating, the research on the energy consumption node of fiber pulp, the fiber-reinforced node and the fiber shape at key nodes, which need different water-removing requirements, need to be further clarified.

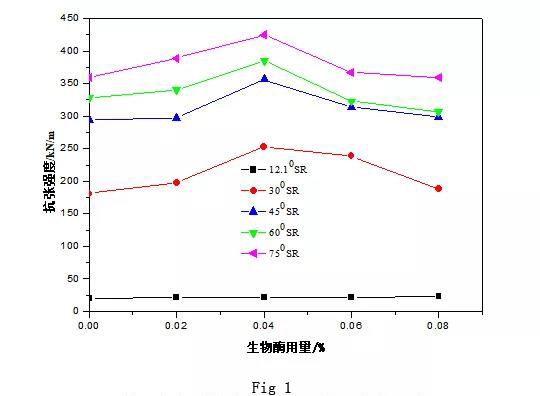

Effect of biological enzyme-assisted refining on tensile strength of paper

It can be seen from Fig. 1 that as the target beating degree increases, the tensile strength of the paper increases continuously and reaches a maximum at a beating degree of 750 SR. With the increase of the amount of biological enzymes, the tensile strength of the paper increases first and then decreases. The enzyme-assisted refining has a node for the improvement of the tensile strength of the paper. In the process of pretreating the pulp fiber, the cellulase firstly performs biological enzyme modification on the surface of the fiber or the fine fiber on the surface of the fiber, and the surface of the fiber is relaxed to a certain extent, and promotes the water swell and fibrillation of the fiber cell; The surface of the fiber cells is raised to increase the specific surface area of the individual fibers, and the macroscopic performance is an increase in the fiber binding force and an increase in the strength of the paper. When the amount of biological enzymes increases again, the surface modification of the fiber is intensified, and the binding force of the individual fibers is increased, but the strength of the fiber itself is lowered, and the macroscopic table shows an increase in the fiber binding force, but the tensile strength of the fiber is decreased. When the amount of biological enzyme added was 0.04%, the tensile strength of the paper appeared to be an enhanced node.

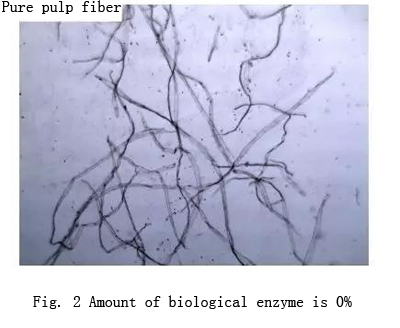

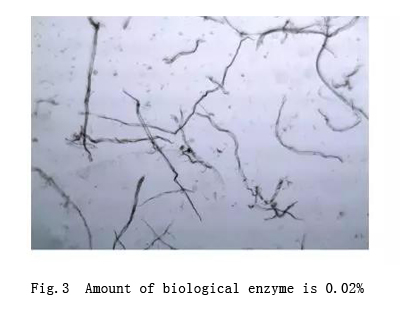

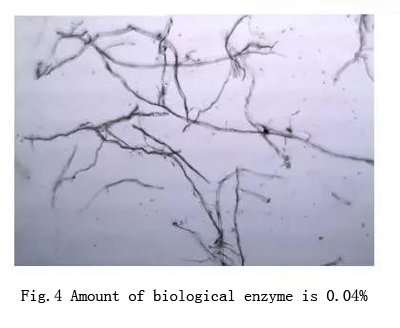

Cellulase-assisted beating affects fiber morphology

The effect of bio-enzyme-assisted refining on the surface morphology of pulp fibers is shown in Figures 2-4. It can be seen that the surface of the pure pulp fiber is smooth and compact, as shown in Fig. 4; when the amount of biological enzyme added is 0.02%, the fiber becomes loose, rough, messy and soft, as shown in Fig. 5; At 0.04%, the fibers become looser and the surface of the fibers is more fluffy. During the refining process, the fibers have been cut and some fine fibers are produced, as shown in Fig. 6. It can be seen that after pretreatment with biological enzymes, pulp fibers appear surface fuzzing and fibrillation. As the amount of enzyme increases, the fiber length decreases, the fine fiber content increases, and the paper strength decreases.

Conclusion

The bio-enzyme has an enhanced node in the paper-forming strength of the bio-enzyme-assisted refining. The tensile strength node appears at 0.04% of the bio-enzyme addition, and the burst strength and tear strength node appear at 0.02% of the bio-enzyme addition. At the paper strength node, compared with no bio-enzyme slurry, the tensile strength of the paper with a beating degree of 30°SR increased by 39.79%, and the tear strength of the paper with a beating degree of 30°SR increased by 18.84%, respectively. The paper breaking strength of 60 ° SR was increased by 49.75%. Fiber morphology analysis showed that the number average length of pulp fibers increased first and then decreased with the increase of bio-enzyme addition. When the amount of the biological enzyme exceeds 0.02%, the fibers become loose, and the surface of the fiber is raised and finely fibrillated.